At my laundry, we do a lot of commercial and residential drop-off laundry. Unfortunately, I have a tough time getting white socks to look really white. Any suggestions?

At my laundry, we do a lot of commercial and residential drop-off laundry. Unfortunately, I have a tough time getting white socks to look really white. Any suggestions?

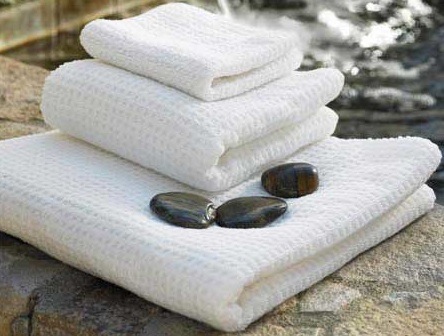

Also, we wash white towels for a local physical therapist. We routinely receive towels with makeup stains that are difficult to remove. We’ve had some success with a product called TarGo. However, can you recommend anything else?

Any time you’re dealing with white items my suggestion is to use hot water and a “built detergent,” which basically is a stronger detergent with some alkali in it. I also would recommend using chlorine bleach.

In addition, one of the most important things to remember when trying to get whites whiter is not only using the right chemicals with the proper water temperature, but also washing those garments for the correct amount of time. These items may require a slightly longer wash cycle. If you’re currently using a 12- to 14-minute wash cycle, perhaps try lengthening it to 20 minutes. A longer cycle with the right chemicals in hot water should get just about any cotton or synthetic blend as white as can be.

Regarding the white towels, I once again would suggest using a high-quality built detergent in hot water with chlorine bleach. When using a stain remover – such as TarGo or Laundry Wetspo – on the makeup stains, use a “spotting method” to remove the makeup. In other words, don’t dump it into the wash cycle; apply it directly to the towel stains and then run these items through a typical wash cycle.

For both the towels and the socks, be sure that you’re using the right amount of chlorine bleach. If you’re using an over-the-counter bleach product, the potency can vary anywhere from 1.5 percent chlorine to 6 percent – whereas a commercial-grade chlorine bleach is typically about 8 percent chlorine. Try to use bleach that has the greatest amount of chlorine.

I have a small, unattended, 24-hour laundromat located in Alaska. The average temperature here is probably about 40 degrees, and my gas dryers get makeup air from a large opening to an outside wall. This has created some problems, including an extremely high cost of operation.

I think I have figured out a couple of different ways to improve this situation. One way is with air pressure, and the other with an electrical sensor that would allow outside air, based on the number of machines in operation. However, my problem is finding the control modules to activate the fans to provide the makeup air. I believe this would provide a significant savings. What are your thoughts on this?

I’m familiar with what you are trying to accomplish, and I’d like to offer a few words of caution.

Your dryers are very sensitive to air pressure. They are made to operate in a stagnant air situation; in other words, air that is not induced – air that is just lying there and being sucked in by the flame of the dryer.

The air that’s sucked in by the dryer has to be replaced from an outside source. Normally, when you have openings, the air is drawn in naturally, and it remains in a “lazy state” while it is being used.

By contrast, if you install air inducers, it will be hard to control how much volume you’re going to pump in – and at what times. You might end up being as inefficient with activated air that is brought in through squirrel-cage fans as you are currently – and you might not accomplish anything.

My experience with this type of activation of air behind dryers hasn’t worked out too well. The modules get linted up, and they don’t work properly. I’ve also been in laundries where the air blasts in like a tornado.

My advice to you would be to call the manufacturer of the particular dryers that you have in your store and talk to someone in detail about what you want to do and how you want to do it. This will give you a better idea of what your best course of action should be.